Wayland Industries provides the highest quality stainless steel sanitary fittings, valves, and tubing to distributors throughout North America. Our products are certified to 3-A sanitary standards. All Wayland products are produced by ISO 9001 certified suppliers. From manufacturing to final packaging, our suppliers’ rigid quality control systems ensure Wayland Industries products always comply to our industry’s highest specifications.

Full Traceability and Certification

- Traceability: 100% of Wayland products are marked with our logo, size, alloy, part number, heat number, country of origin and mill order number for complete traceability of all 304 and 316L alloy parts used in manufacturing.

- Material Test Reports (MTR): Any Wayland Heat Number references it’s EN 10204-3.1 material test report. Reports are available upon request for all 304 and 316L products and our website offers these MTRs 24/7.

- Certification: Wayland Industries maintains 3-A certifications for all applicable products. All gaskets and seals are FDA certified.

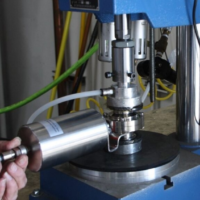

Inspection and Testing

Inspection and testing are performed throughout the entire manufacturing process, from initial raw material inspection through final packaging and pre-shipment verification. Our quality systems and process capabilities ensure Wayland products are manufactured to 3-A specifications. Wayland Industries products and processes are continuously monitored and follow these quality inspections and tests:

- Suppliers’ ISO 9001 quality systems are evaluated and monitored

- Verification of incoming material and markings to mill certifications

- Positive Material Identification (PMI) confirming material chemistry

- Dimensional inspection to Wayland manufacturing tolerances

- Surface finish inspection

- Borescope inspection (tubing)

- Pressure testing (valves)

- Other testing and inspection procedures available per customer request